STREAMLINE DATA CENTER ENVIRONMENTAL MONITORING WITH SENSORS

In an era where digital connectivity powers nearly every aspect of modern life, data centers are the unsung heroes behind the scenes. From hosting virtual clouds to enabling artificial intelligence and cryptocurrency transactions, these facilities handle immense volumes of data.

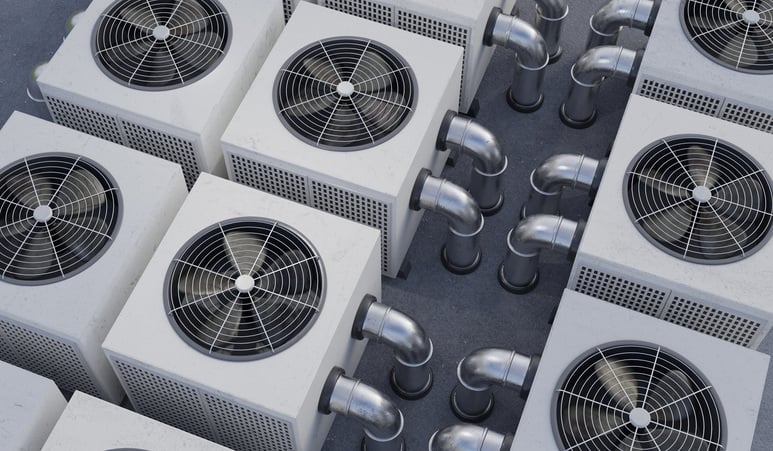

However, this critical infrastructure requires meticulous environmental control to function reliably and efficiently. HVAC (heating, ventilation, and air conditioning) is among the most vital systems for ensuring seamless operation, all while meeting the unique challenges of computing center environments.

Integrated into data center HVAC systems, sensors do much more than monitor temperature. They provide real-time insights into humidity, airflow, pressure, and air quality, helping operators make data-driven decisions to optimize performance. As server farms grow in size and complexity, sensors are becoming indispensable tools for achieving efficiency, reliability, and compliance with evolving design standards.

Let’s explore how sensors address the challenges of data center environmental monitoring while adapting to ever-evolving regulations.

HOW DATA CENTER GROWTH IS TRANSFORMING HVAC NEEDS

The demand for data centers has exploded due to the rise of AI, cryptocurrency mining, and digital data consumption. In the first half of 2023, server farm construction hit 287.6 megawatts — a 70% increase over the previous year — with the market projected to grow from $301.8 billion in 2022 to $622.4 billion by 2030.

This growth brings challenges, including:

- Energy consumption: Server farms consume vast amounts of electricity, contributing to carbon emissions.

- Sustainability: Operators must balance performance with environmental impact.

- Reliability: Downtime can lead to data loss and millions of dollars lost.

Advanced HVAC systems, integrated with sensor technology, are vital to addressing these challenges.

WHY DATA CENTER ENVIRONMENTAL MONITORING IS THE #1 PRIORITY

While data center HVAC systems serve multiple purposes, the top priority has always been controlling temperature. Unlike homes or offices, where temperature requirements vary, these IT hubs require consistent and precise cooling throughout the facility 24/7.

Efficient HVAC systems achieve three key objectives:

- Protecting equipment and budgets: Overheating damages sensitive hardware, leading to costly repairs. Proper cooling minimizes these risks while keeping energy costs in check.

- Ensuring operational efficiency: Maintaining optimal temperature and humidity levels extends equipment lifespan, reduces energy use, and minimizes environmental impact.

- Maximizing uptime and reliability: Reliable HVAC solutions prevent disruptions by maintaining consistent conditions.

ADVANCED SENSOR TECHNOLOGY: THE KEY TO HVAC EFFICIENCY

Modern computer center HVAC systems are far more advanced than traditional heating and cooling systems. They rely on an array of sensors to monitor and manage environmental conditions. Beyond temperature, these systems track humidity, air quality, and pressure metrics to maintain optimal functionality.

Key sensors for data center HVAC design include:

Sensor Type |

Function |

Purpose/Benefit |

|

Humidity sensors |

Prevent condensation (caused by high humidity) and static electricity (caused by low humidity) |

Protect sensitive equipment from moisture damage and static-related malfunctions |

|

Differential pressure sensors |

Monitor airflow by detecting pressure differences |

Ensure consistent cooling and prevent blockages in airflow systems |

|

Indoor air quality sensors |

Measure pollutants like CO2 and volatile organic compounds |

Protect equipment and personnel from harmful pollutants |

|

Dew point sensors |

Monitor moisture levels in liquid cooling systems |

Avoid condensation buildup that can damage equipment or reduce cooling efficiency |

|

Underfloor leak detection sensors |

Identify water leaks early |

Minimize damage caused by water leakage in underfloor cooling systems |

|

Fire suppression sensors |

Detect smoke to activate fire suppression systems |

Protect critical infrastructure by preventing fire damage |

|

Carbon monoxide (CO) sensors |

Monitor CO levels |

Ensure a safe environment for personnel |

|

Temperature sensors |

Provide real-time data on ambient, surface, and system temperatures |

Enable precise climate control |

Hello, world!

4 CRITICAL DESIGN CONSIDERATIONS FOR DATA CENTER HVAC SYSTEMS

Designing an HVAC system for a server farm involves more than selecting a powerful cooling unit. It also requires a tailored approach based on the facility’s size, equipment density, and energy requirements. Key factors include:

- Space: Larger facilities need robust cooling solutions, while smaller ones risk overcooling if HVAC output is excessive.

- Equipment heat output: High-density equipment layouts generate significant heat. Cooling systems must match the heat load.

- Energy efficiency: Inefficient systems can lead to higher operational costs and larger carbon footprints.

- Human occupancy: While server farms have limited personnel, small office areas require separate cooling considerations for comfort.

Meeting these demands often involves partnering with experienced HVAC manufacturers and sensor technology providers. These experts tailor solutions to the facility’s unique needs, ensuring optimal performance and reliability.

The Evolving Landscape of Cooling Technologies

Traditional HVAC systems are no longer sufficient to meet the demands of high-density IT hubs. New cooling methods, integrated with advanced sensor technology, are reshaping how enterprise-level data facilities manage heat. When combined with precise sensor integration, these methods ensure sustainable and reliable cooling even as equipment density and performance demands increase:

Immersion Cooling

Servers are submerged in a thermally conductive liquid that absorbs heat directly. Sensors for pressure, flow, and temperature are essential for monitoring this process.

Custom air handlers

These systems use direct expansion cooling and cooling towers for efficient heat dissipation. They rely on temperature, humidity, and air quality sensors for optimal performance.

Fan arrays with liquid chillers

Combining air and liquid cooling, these systems use fans to circulate cooled air. Sensors monitor airflow, vibration, and power usage to ensure efficiency.

The Role of Sensor Manufacturers in Computing Center Environmental Monitoring

Developing highly efficient HVAC systems requires expertise in sensor integration. Partnering with experienced sensor manufacturers ensures:

Tailored solutions: HVAC systems are customized to meet the unique needs of each data center.

Improved performance: Real-time data enables fine-tuning.

Cost savings: Early detection of inefficiencies or failures reduces downtime and maintenance.

Ensuring Long-Term Reliability and Sustainability

As computing centers grow in scale and complexity, their HVAC systems must evolve to meet higher demands. Cutting-edge sensor technology enables these facilities to achieve unparalleled efficiency, reliability, and sustainability. By protecting critical infrastructure and reducing environmental impact, these advancements support the continued growth of the digital age.

The Cost of Poor Temperature Management in Data Center Environmental Monitoring

On the other end, low temperatures can create condensation, causing shorts and corrosion, and reducing cooling efficiency. The challenge lies in striking a balance between cooling and energy efficiency — a task made possible by advanced temperature sensors.

What Are Data Center Temperature Sensors?Temperature sensors act as the eyes and ears of a server farm’s climate control system, providing real-time insights into thermal conditions. These sensors come in various types, each tailored for specific applications:

Choosing the right sensor involves considerations such as precision, response time, and compatibility with existing HVAC systems. |

KEY DESIGN CONSIDERATIONS FOR SENSOR SYSTEMS

Strategic placement ensures comprehensive temperature monitoring.

Key locations include:

- Elevation-based placement: Sensors at varying heights detect vertical temperature gradients.

- Airflow monitoring: Sensors near cooling coils, intake, and exhaust points track air circulation effectiveness.

- Fluid temperature monitoring: For hydronic cooling systems, sensors ensure liquid cooling efficiency.

- Proximity to equipment: Sensors near server racks monitor heat generation, preventing localized overheating.

The size and layout of IT hubs dictate the number of sensors needed. Monitoring dead air spaces — areas with restricted airflow — helps prevent hot spots and maintain consistent temperatures.

High-quality IT hub sensors provide precise readings, often within fractions of a degree. This level of accuracy is crucial, as small fluctuations can significantly impact equipment performance.

Reliable sensors also minimize maintenance needs and downtime, ensuring 24/7 operation.

Most HVAC systems rely on sensor feedback to adjust cooling and airflow. Wireless sensors streamline integration by allowing flexible placement and eliminating wiring constraints.

Monitoring dead air spaces further ensures even temperature distribution and hotspot prevention.

Partnering With A Data Center Sensor Manufacturer

Collaborating with advanced sensor manufacturers ensures tailored solutions that meet a computing center's unique needs. The benefits of working with experts include:

Expertise and knowledge: Manufacturers offer an in-depth understanding of sensor technology and performance.

Customization options: Sensors can be designed for specific precision, response times, and integration needs.

Reliability and quality: Rigorous testing ensures heavy-duty sensors perform consistently in critical environments.

Ongoing support: Manufacturers provide technical assistance, troubleshooting, and updates for long-term success.

Building strong partnerships with sensor manufacturers ensures enterprise-level data facilities stay ahead in efficiency and reliability.

WHY HUMIDITY CONTROL MATTERS IN SERVER FARM ENVIRONMENTAL MONITORING

Excessive moisture fosters corrosion on metal components and increases the likelihood of condensation, resulting in short circuits and equipment failure. Humidity is one of the most critical environmental factors in data centers, as improper levels can severely impact sensitive electronics. Excess moisture or low humidity levels in server farms can lead to costly downtime, equipment damage, and data loss. Understanding the challenges and deploying advanced humidity control strategies is essential to maintaining operational efficiency.

- Equipment performance: Excessive moisture from high humidity can cause condensation on sensitive components, leading to malfunctions or permanent damage. Corrosion is another concern, particularly for metal parts in servers and networking hardware.

- Static electricity: Low humidity increases the risk of electrostatic discharge, which can silently damage electronics. Even a single instance of static discharge can compromise critical equipment.

- Condensation and corrosion: Excessive moisture fosters corrosion on metal components and increases the likelihood of condensation, resulting in short circuits and equipment failure.

Measuring Humidity: Key Metrics

Understanding how to measure humidity helps computing centers maintain optimal environmental conditions. Common metrics include:

|

Metric |

Description |

Use/Benefit |

|

Relative humidity (RH) |

Measures the percentage of moisture in the air relative to its capacity to hold water at a given temperature |

Commonly used, but RH can fluctuate with temperature changes, requiring careful monitoring for precision |

|

Dew point (DP) |

Indicates the temperature at which air becomes saturated, leading to condensation |

Preventing moisture accumulation on sensitive equipment and ensuring operational stability |

|

Wet bulb temperature |

Combines heat and humidity to reflect the lowest temperature air can reach through evaporation |

Assessing moisture movement (e.g., exfiltration) and identifying condensation risks |

|

Water vapor pressure |

Measures the mass of water vapor in the air, independent of temperature |

An additional layer of understanding for precise humidity control in sensitive environments |

Sources of Moisture in Server Farms

Humidity in data centers originates from several sources:

- Outside air: Improperly conditioned air introduced through HVAC systems can disrupt environmental stability.

- Human activity: Personnel working within the facility contribute to moisture, requiring careful monitoring to offset these impacts.

- Liquid cooling systems: While efficient at managing heat, liquid cooling systems can inadvertently introduce moisture through leaks or condensation if not meticulously controlled.

Understanding and managing these sources is critical to maintaining a balanced indoor environment.

HUMIDITY CONTROL STRATEGIES USING SENSOR TECHNOLOGY

Modern computing centers rely on advanced sensor technology to monitor and manage humidity levels in real time. These systems are deeply integrated with HVAC setups, providing precision control and rapid adjustments as needed.

Two primary types of humidity sensors dominate server farm applications:

- Capacitive sensors: These sensors detect changes in electrical capacitance caused by fluctuations in humidity. They offer:

- High accuracy and stability: Ideal for long-term monitoring with minimal drift.

- Fast response times: Crucial for preventing condensation or mitigating static risks.

- Durability: Withstands extreme conditions, ensuring reliable performance.

- Resistive sensors: By measuring changes in electrical resistance in response to moisture, resistive sensors provide reliable readings. However, capacitive sensors often outperform them in terms of accuracy and durability.

HOW DATA CENTER TEMPERATURE AND HUMIDITY SENSORS RELATE

Temperature sensors complement humidity sensors by providing essential data for climate control. Since hotter air holds more moisture, temperature fluctuations directly impact relative humidity levels. Accurate temperature monitoring ensures that HVAC systems adjust cooling processes to maintain a stable environment.

Airflow and Pressure: The Hidden Players in Humidity Control

Effective humidity management isn’t just about moisture; it’s also tied to airflow and pressure control. Proper air circulation prevents moisture accumulation and minimizes condensation risks, while pressure management ensures that air flows correctly to maintain environmental stability.

Maintaining slightly higher internal pressure prevents external air — which often contains contaminants and moisture — from infiltrating the facility. This "clean room" approach ensures that only properly conditioned air circulates within IT hubs.

Tracking pressure differences across HVAC components, like filters and ducts, helps identify blockages or inefficiencies. This monitoring ensures optimal airflow and prevents hot or humid air pockets from forming.

Advanced Pressure Sensors for Data Centers

Pressure sensors provide crucial feedback for maintaining balanced airflow and environmental stability. Common types include:- Low static pressure sensors: Designed for high sensitivity, these sensors detect minor changes in pressure, allowing for immediate adjustments.

- Differential pressure sensors: These monitor airflow across filters or ducts, identifying obstructions that could disrupt climate control.

WHY ARE DATA CENTER DESIGN STANDARDS IMPORTANT?

Data center design standards are more than guidelines; they also are critical to ensuring efficient, safe, and compliant operations. Below are the key reasons these standards are essential:

Focus Area |

Description |

Benefits |

|

Energy & environmental impact |

Server farms consume significant electricity, contributing to carbon emissions and resource depletion. Design standards aim to minimize energy use and environmental impact |

Reduced carbon footprint, sustainable resource use, and lower operational energy costs |

|

Safety |

IT hubs house critical infrastructure vulnerable to fires, electrical hazards, and leaks. Standards emphasize preventive measures like fire detection, electrical safety, and environmental monitoring |

Protection of critical equipment, minimized risk of disasters, and enhanced safety for personnel |

|

Reliability |

Unplanned downtime can cause financial losses, reputational damage, and data loss. Standards ensure redundancy, robust infrastructure, and reliable cooling systems |

Improved uptime, operational continuity, and protection against catastrophic failures |

|

Efficiency |

Efficiency is achieved by optimizing energy use, employing advanced cooling systems, and using sensor technology |

Lower operational costs, improved performance, and reduced energy waste |

|

Regulatory compliance |

Adherence to local, national, and industry-specific regulations is mandatory for computing center operators |

Avoidance of fines and legal issues, improved reputation, and alignment with sustainability goals |

Hello, world!

KEY DATA CENTER REGULATIONS

Enterprise-level data facilities are governed by various standards and regulations designed to ensure efficiency, reliability, and safety. These guidelines are crucial in computing center operations, from cooling systems and power distribution to fire protection and scalability. Below are some of the most influential standards and how sensor technology supports compliance:

Standard/Regulation |

Focus Area |

Role of Sensors |

|

Optimal temperature and humidity ranges to prevent equipment failure and reduce energy waste. |

Emphasizes placement of temperature sensors (top, middle, bottom of racks) and humidity sensors for improved cooling accuracy. |

|

|

Energy-efficient strategies such as airflow containment and liquid cooling. |

Uses real-time temperature, airflow, and humidity sensors for dynamic monitoring and energy optimization. |

|

|

Fire protection, ensuring uptime and preventing catastrophic losses. |

Mandates smoke detectors and temperature sensors to detect fire risks early. |

|

|

Fire safety in telecommunications and data center facilities. |

Requires temperature and humidity sensors to monitor critical conditions and prevent fire hazards. |

|

|

Efficient, reliable, and scalable data center infrastructure. |

Uses temperature and airflow sensors for fault tolerance, PUE compliance, and critical environmental monitoring. Supports real-time monitoring for scalability. |

|

|

Energy efficiency regulations for HVAC and lighting. |

Uses airflow sensors for cooling optimization, temperature and humidity sensors for efficiency, and real-time data for dynamic HVAC adjustments. |

|

|

Energy-efficient federal computing centers. |

Employs temperature, humidity, and airflow sensors for optimal cooling, dynamic power management, and compliance with FEMP sustainability goals. |

|

|

Sustainability and efficiency in European IT hubs. |

Uses sensors for energy efficiency, reliability, and modular cooling systems. Tracks real-time carbon footprints and supports scalability. |

|

|

Sustainability and resource optimization in operations. |

Uses sensors to monitor energy efficiency, emissions, and water consumption while enabling continuous environmental improvements. |

Energy Efficiency and Sustainability in Data Center Design

As demand for digital services grows from both consumers and businesses, data centers face mounting pressure to reduce energy consumption, minimize carbon footprints, and comply with environmental regulations. Sensor technology plays a pivotal role in meeting these challenges.

By providing real-time insights into temperature, airflow, and humidity, sensors allow server farm operators to:

- Optimize cooling strategies to reduce energy costs

- Prevent overheating, hot spots, or equipment failure

- Meet environmental and energy efficiency regulations

DATA CENTER ENVIRONMENTAL MONITORING: ACHIEVING EXCELLENCE THROUGH SENSOR INTEGRATION

The future of data center functionality lies in the precise control of critical environmental conditions, made possible by advanced sensors. These devices are more than just monitoring tools — they are the backbone of server farm HVAC systems, ensuring that working parameters stay within safe ranges. Sensors safeguard the operational integrity of these critical facilities by preventing equipment failures, reducing energy waste, and supporting sustainability.

As the demand for high-performing computing centers continues to grow, investing in state-of-the-art sensor technology is no longer optional — it’s a necessity. Partnering with experienced sensor manufacturers enables designers and engineers to create smarter, more efficient environments, futureproofing their facilities while addressing the challenges of scale, sustainability, and compliance.

Amphenol Advanced Sensors: Your Partner in Compliance

Explore how Amphenol Advanced Sensors can help your data center achieve compliance, optimize energy efficiency, and drive sustainability: